Explore our range of services below and discover how we can assist you to fulfill your specific needs.

At Pure Integrity, we understand the importance of process safety in high-risk industries like oil and gas and process industries. Our team of experienced and certified professionals are committed to providing comprehensive consulting services on process safety to assist you in minimizing risks and safeguarding your assets, reputation and personnel. We work closely with our clients to develop customized solutions that suit their specific needs and objectives, and conform to industry standards and regulatory requirements. From hazard identification and risk assessment to SIL verification and HAZOP studies, we have the expertise and knowledge to help our clients achieve their safety goals.

We have experience in conducting various risk studies globally covering offshore and onshore facilities of diverse complexities.

Hazard and Operability (HAZOP) study is a formal technique to systematically examine the process design of a facility, with due regard for the planned mode of operation, inspection and maintenance. The objectives of the HAZOP study are to:

Go trough the process and relevant utility systems in a structured and systematic way to identify the causes of potential safety and environmental hazards and operability issues;

Assess potential consequences, should a hazardous condition evolve into an accident;

Identify safeguards present in the current design that either prevent the accident from occurring or mitigate the consequences of an accident; and

Make judgements whether selected design or operational safeguards are adequate, or if further mitigating actions are required

Hazard Identification (HAZID) study is a valuable tool for identifying potential hazards associated with a process or system. The objectives of HAZID study are to:

Identify potential hazards and reasonably foreseeable accidents within the overall design of the facilities;

Assign a risk category to each hazard and rank them in accordance with the risk;

Identify any safeguards that is available within the current design (i.e. any measure provided to prevent, control, mitigate, or enable emergency response and recovery); and

Provide recommendation(s) for further safeguards where deemed necessary.

Alarm management is systematic approach to managing essential alarm in oil & gas industry and process industry to ensure safe operation. As alarms are essential in alerting operators to abnormal or potential hazardous situation, however excessive number of alarms or poorly designed alarm systems can lead to increased risk of incidents or errors.

Alarm management aims to optimize the performance of alarm systems by ensuring that alarms are meaningful, reliable, and effectively communicated to operators through Alarm Rationalization Study.

Bow-tie analysis provides a structured framework for identifying and visualizing potential risks and the corresponding preventive and mitigative barriers. The technique uses a graphical representation resembling a bow-tie, with the hazard or event of concern in the center, the threats or causes on one side, and the consequences and preventive/mitigative barriers on the other side.

The bow-tie diagram helps to illustrate the cause-and-effect relationship between hazards, threats, consequences, and control measures. It helps organizations evaluate whether the risk reduction measures identified through bow-tie analysis are sufficient to meet the ALARP criteria. If the analysis reveals that the risks are not reduced to an acceptable level, additional control measures can be identified and implemented to further mitigate the risks and achieve an ALARP state.

At Pure Integrity, we understand the importance of functional safety in high-risk industries like oil and gas and process industries. Our team of experienced and certified professionals are committed to providing comprehensive consultation services, ensuring that our clients' equipment, processes, and systems are designed, implemented, and operated with the highest level of safety integrity.

At Pure Integrity, we believe that functional safety is not just a legal requirement, but a moral obligation, and we are dedicated to making the world a safer place, one project at a time.

SIL Classification Study refers to the process of allocating Safety Integrity Level (SIL) to a specific safety function within a system in accordance with IEC 61511 throughout its Safety lifecycle. The assigned SIL level reflects the reliability required for a safety function to achieve its intended risk reduction and are categorized from SIL 1 to SIL 4. It also takes account of the severity of potential consequences, the frequency of exposure to hazards, and the reliability of the other independent layer of safety function.

Pure Integrity Sdn Bhd offers SIL Classification services that ensures method chosen are relevant to our clients’ internal standards. Our services cover:

Layers of Protection (LOPA)

Risk Matrix

Risk Graph

Event Tree Analysis (ETA)

Safety Requirements Specification (SRS) is a document that specify information regarding safety-related requirements for a Safety Instrumented Function (SIFs). It is an essential process that requires updating and maintenance throughout overall functional safety lifecycle to ensure that the SIFs are maintained and functioning as defined clearly on SRS.

The SRS in Functional Safety typically includes the following information:

SIFs Objectives and its safe state: Clearly states objectives that need to be achieved by the system and its end safe state.

Safety Functions: Identifies and describes the safety functions that the system should perform to mitigate or prevent specific hazards or risks.

Safety Integrity Level (SIL): Specifies the required Safety Integrity Level for each safety function, based on the risk assessment and the severity of potential consequences.

Functional Requirements: Describes the details related to safety, including the inputs, outputs, behavior, and performance of the safety functions.

Verification and Validation: Outlines the procedures and methods to verify and validate that the safety requirements are met, including testing, inspections, and other verification activities.

Documentation and Reporting: Specifies other documents that is required, such as safety manuals, FMEA, and etc.

The SRS helps to establish a common understanding among system designers, safety engineers, regulators, and end-users, regarding the safety objectives, functionality, and performance of the system.

SIL (Safety Integrity Level) Verification is a process used to assess and confirm whether the Safety Instrumented Functions (SIFs) within a system have achieved its required safety integrity level. It ensures that SIFs effectively mitigate risks identified in HAZOP to ALARP.

During SIL Verification, the performance of SIFs are evaluated based on IEC 61508 & IEC 61511. It is assessed based on three criteria:

Probability of Failure on Demand (PFDavg): How likely the whole SIF Loop which includes Sensor, Logic Solver and Final Element to fail on demand. This includes analyzing the failure rates of individual components, diagnostic coverage, and proof test intervals

Architectural Constraint: Redundancy required for each element to achieve target SIL. It enhance system resilience, minimize the impact of faults, and maintain the required safety performance even in challenging conditions or in the presence of multiple failures.

Systematic Capability: Capability of each element used within the SIF Loops as per its SIL target

Our team of expert consultants specialize in the development of SIL Verification procedures that are precisely tailored to the needs and preferences of our clients.

SIL Validation focuses on the operational phase of the safety system. It involves validifying and confirming that the installed SIFs are procured, installed and maintained as per Safety Requirement Specifications (SRS) and provides the required risk reduction or risk mitigation. SIL Validation activities include functional testing, reliability analysis, proof testing, and performance evaluation to ensure that the safety system meets the specified SIL level in real-world operating conditions. It is performed at site after installation of all SIL certified components of the SIF loop.

Pure Integrity Sdn Bhd has wealth of experience performing on-site SIL validation post-installation to ensure robust, reliable, and capable safety system.

Functional Safety Assessment (FSA) is a systematic and independent evaluation of the safety systems to determine if the safety system does meet the specification and actually achieve functional safety (freedom from unacceptable risk). It main function is to support a decision to either progress to the next phase of the Safety lifecycle once all necessary measures are in place. It aims to assess and verify the level of compliance with functional safety standards, guidelines, and best practices.

The Functional Safety Assessment (FSA) is required as per IEC 61511 and done prior to introduction of hazards at three different stages. It is done during:

After Hazard studies and Risk Assessment

Before introduction of Hazards and post SIL Validation as per Safety Requirements Specification (SRS)

Periodically done once plant or system have been operating a few years as form of re-validation and update based on accumulated plant operating experience

Pure Integrity Sdn Bhd will ensure that FSA done will provide insights on functional safety standards compliance, identify areas for improvement, and enable the implementation of corrective actions.

At Pure Integrity, we pride ourselves on providing exceptional technical services to our clients. Our team of experts has years of experience in the industry and is dedicated to delivering innovative solutions tailored to the unique needs of each client. From RAM studies to Asset , we offer a full range of technical services that help our clients achieve their goals efficiently and effectively.

Our commitment to quality, safety, and customer satisfaction sets us apart from the competition. Contact us today to learn more about how our technical services can help your business succeed.

Asset integrity refers to the condition in which an asset is operated and maintained, aiming to minimize risks that could result in safety hazards, environmental harm, production disruptions, or financial losses. By conducting effective inspections and managing risks diligently, these activities can reduce the likelihood of major failures and breakdowns, enhance operational efficiency, and extend the lifespan of assets.

Pure Integrity Sdn Bhd offers a comprehensive range of services for Asset Integrity, tailored to meet the unique needs of our clients. Our services include:

Asset Register in accordance to ISO 14224

Equipment Criticality Assessment (ECA)

Safety Critical Element (SCE) Assessment

Failure Mode and Effects Analysis (FMEA)

Equipment Reliability Strategy (ERS)

Inspection, Testing and Preventive Maintenance (ITPM)

Equipment Maintenance Plan (MPLAN)

Asset Life Extension Study (ALES)

We have expertise in doing Risk Based Inspection (RBI) and the management of RBI as part of a larger reliability management and process safety management framework. This includes:

Risk analysis;

Development of inspection plans;

Repairs and modifications;

Performance management; and

Auditing

We also familiar with local DOSH regulation and requirements.

We have expertise in developing, refining, and reviewing guideline documents, procedures, recommended practices and work instructions. We can assist from document concept development, to writing the content, to producing art work and the finished document.

We currently have a 3-year contract with a major upstream oil & gas company to support the development and update of their technical documents.

We can assist clients to drive operational excellence in areas such as:

Maintenance: Efficiency, time on tools, backlogs, schedule optimisation, improving first starts;

Reliability: Reliability management framework, bad actor management, 5-why and causal learning;

Commercial Mindset: Margin tracking, visualisation, Kaizen, LEAN.

At Pure Integrity, we are committed to providing top-quality construction and field services to our clients. We take pride in delivering our projects on time and within budget, while ensuring the highest level of safety and quality. Our team of experienced professionals are equipped are dedicated to meeting the unique needs of each and every project. Whether you need site preparation, excavation, foundation work, or general construction services, we have the expertise and resources to get the job done right.

With our proven track record of success and our unwavering commitment to excellence, you can trust Pure Integrity for all your construction and field service needs.

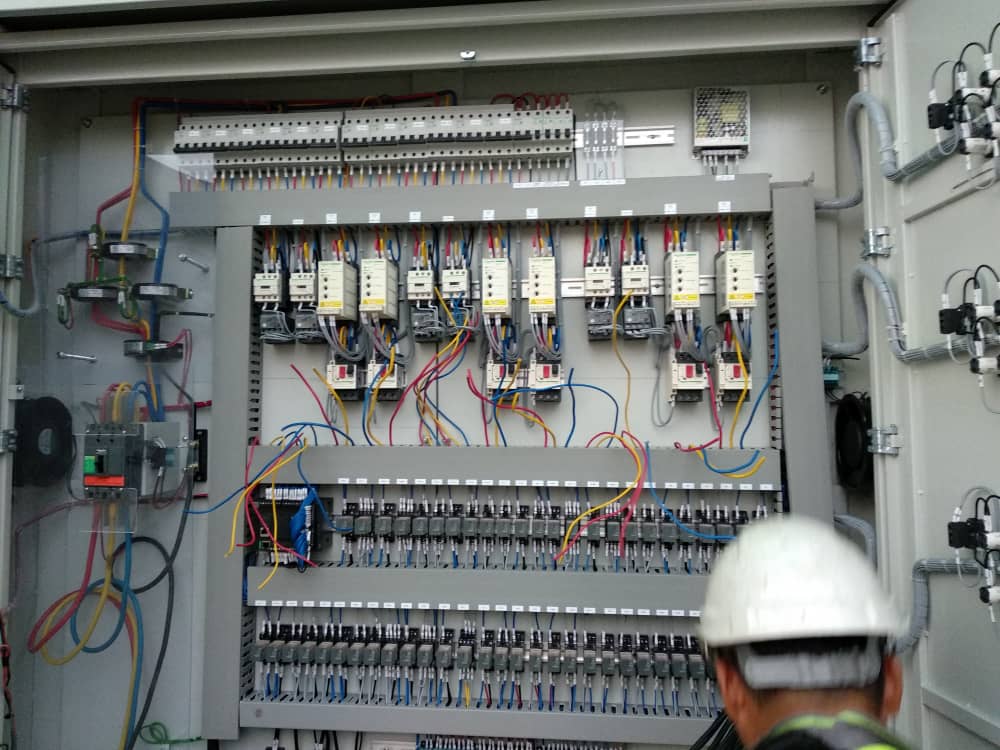

We have strong expertise in the area of electrical and instrumentation which covers procurement, construction, installation, pre-commissioning, commissioning and troubleshooting. This includes:

SIF design and testing;

Motor

Transformer

Substation

Transmitters

Valves

Thermocouples and thermowells

Orifice plates

Sampling probes and Quills

Drafting

At Pure Integrity, we understand the importance of having a highly skilled and knowledgeable workforce. That's why we offer comprehensive training services to equip individuals and teams with the expertise they need to excel in their roles. Our training programs are designed to be engaging and interactive, with a focus on practical, hands-on learning that can be applied immediately in the workplace. Whether you're looking to enhance your existing skills or learn new ones, our expert trainers will provide the guidance and support you need to achieve your goals.

With Pure Integrity's training services, you can invest in the development of your workforce and drive the success of your business.